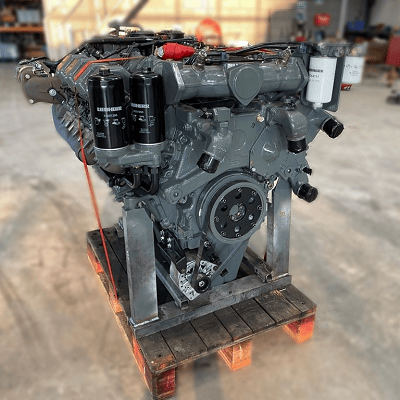

When it comes to heavy machinery, reliability and power are paramount. Liebherr, a name synonymous with innovation and excellence in engineering, stands tall as a pioneer in the realm of heavy equipment and machinery. From towering cranes to robust excavators, Liebherr’s engineering prowess extends to the heart of these machines. We delve into the world of dyno testing a Liebherr engine, uncovering the meticulous process behind unleashing the raw power concealed within. Before we embark on the journey of dyno testing, it’s crucial to understand the foundation upon which Liebherr engines are built. With decades of engineering expertise and commitment to quality, Liebherr engines are crafted to withstand the most demanding environment and deliver unparalleled performance. Each component is meticulously designed and rigorously tested to ensure reliability, efficiency and longevity. 1 Preparation: The engine undergoes meticulous preparation before being mounted onto the dynamo meter. This includes ensuring all connections are secure, fluids are filled to the appropriate levels, and sensors are properly calibrated. 2 Mounting: The engine is carefully mounted onto the dynamometer, a specialized device designed to simulate real-world operating conditions. Precision is paramount during this step to ensure accurate results. 3 Initial checks: Once mounted, a series of initial checks are conducted to verify proper alignment, connection integrity, and functionality of all engine systems. 4 Warm-up: The engine is started and allowed to warm up to operating temperature. This ensures consistent results and minimizes the risk of damage during testing. 5 Baseline testing: With the engine warmed up , baseline tests are conducted to establish initial performance metrics. This includes measuring power output, torque, fuel consumption, and emissions at various RPM levels. 6 Load testing: The engine is subjected to progressively increasing loads to simulate different operating conditions, such as idle, partial load and full load. This allows engineers to assess performance across the entire operating range and identify any potential issues or optimization. 7 Data analysis: Throughout the testing process, data is continuously collected and analyzed in real-time. Advanced instrumentation and software are used to monitor performance metrics and identify trends or anomalies. 8 Optimazation: Based on the data analysis, adjustments may be made to optimize engine performance. This could involve fine-tuning fuel injection timing, adjusting air-fuel ratios, or optimize turbocharger boost pressure. 9 Validation: Once testing is complete, the results are meticulously reviewed and validated against predetermined criteria and specifications. Any deviations or anomalies are thoroughly investigated to ensure accuracy and reliability. 10 Reporting: Finally, a comprehensive report is generated detailing the results of the dyno testing, including performance metrics, observations, and any recommendations for further optimization or refinement. Dyno testing a Liebherr engine is more than just a routine procedure – it’s a testament to the unwavering commitment to excellence that defines Liebherr’s engineering philosophy. By subjecting their engines to rigorous testing and analysis, Liebherr ensures that each engine delivers the uncompromising performance, reliability, and efficiency that customers expect. In conclusion, dyno testing a Liebherr engine is not just about measuring power output. It’s about unlocking the true potential of these remarkable engines and ensuring they exceed expectations in the most challenging environments imaginable. composite sealing strip,Two Composite Sealing Strip,Compound Sealing Strip HEBEI JIEXING RUBBER SEALS CO.,LTD , https://www.jiexingrubber.com

The process of a dyno test on a Liebherr engine

The foundation of excellence

The process

The outcome of dyno testing

window.authenticationPopup = {"autocomplete":"off","customerRegisterUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/account\/create\/","customerForgotPasswordUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/account\/forgotpassword\/","baseUrl":"https:\/\/www.cranepartssupply.com\/en\/","customerLoginUrl":"https:\/\/www.cranepartssupply.com\/en\/customer\/ajax\/login\/"}

{

"#authenticationPopup": {

"Magento_Ui/js/core/app": {"components":{"authenticationPopup":{"component":"Magento_Customer\/js\/view\/authentication-popup","children":{"messages":{"component":"Magento_Ui\/js\/view\/messages","displayArea":"messages"},"captcha":{"component":"Magento_Captcha\/js\/view\/checkout\/loginCaptcha","displayArea":"additional-login-form-fields","formId":"user_login","configSource":"checkout"}}}}} },

"*": {

"Magento_Ui/js/block-loader": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fstatic\u002Fversion1728988868\u002Ffrontend\u002FComaxx\u002FPartsSupply\u002Fen_US\u002Fimages\u002Floader\u002D1.gif"

}

}

{

"*": {

"Magento_Customer/js/section-config": {

"sections": {"stores\/store\/switch":["*"],"stores\/store\/switchrequest":["*"],"directory\/currency\/switch":["*"],"*":["messages"],"customer\/account\/logout":["*","recently_viewed_product","recently_compared_product","persistent"],"customer\/account\/loginpost":["*"],"customer\/account\/createpost":["*"],"customer\/account\/editpost":["*"],"customer\/ajax\/login":["checkout-data","cart","captcha"],"catalog\/product_compare\/add":["compare-products"],"catalog\/product_compare\/remove":["compare-products"],"catalog\/product_compare\/clear":["compare-products"],"sales\/guest\/reorder":["cart"],"sales\/order\/reorder":["cart"],"checkout\/cart\/add":["cart","directory-data"],"checkout\/cart\/delete":["cart"],"checkout\/cart\/updatepost":["cart"],"checkout\/cart\/updateitemoptions":["cart"],"checkout\/cart\/couponpost":["cart"],"checkout\/cart\/estimatepost":["cart"],"checkout\/cart\/estimateupdatepost":["cart"],"checkout\/onepage\/saveorder":["cart","checkout-data","last-ordered-items"],"checkout\/sidebar\/removeitem":["cart"],"checkout\/sidebar\/updateitemqty":["cart"],"rest\/*\/v1\/carts\/*\/payment-information":["cart","last-ordered-items","captcha","instant-purchase"],"rest\/*\/v1\/guest-carts\/*\/payment-information":["cart","captcha"],"rest\/*\/v1\/guest-carts\/*\/selected-payment-method":["cart","checkout-data"],"rest\/*\/v1\/carts\/*\/selected-payment-method":["cart","checkout-data","instant-purchase"],"customer\/address\/*":["instant-purchase"],"customer\/account\/*":["instant-purchase"],"vault\/cards\/deleteaction":["instant-purchase"],"persistent\/index\/unsetcookie":["persistent"],"review\/product\/post":["review"],"wishlist\/index\/add":["wishlist"],"wishlist\/index\/remove":["wishlist"],"wishlist\/index\/updateitemoptions":["wishlist"],"wishlist\/index\/update":["wishlist"],"wishlist\/index\/cart":["wishlist","cart"],"wishlist\/index\/fromcart":["wishlist","cart"],"wishlist\/index\/allcart":["wishlist","cart"],"wishlist\/shared\/allcart":["wishlist","cart"],"wishlist\/shared\/cart":["cart"],"catalog\/customproduct\/add":["cart"],"braintree\/paypal\/placeorder":["cart","checkout-data"],"braintree\/googlepay\/placeorder":["cart","checkout-data"]},

"clientSideSections": ["checkout-data","cart-data"],

"baseUrls": ["https:\/\/www.cranepartssupply.com\/en\/"],

"sectionNames": ["messages","customer","compare-products","last-ordered-items","cart","directory-data","captcha","instant-purchase","loggedAsCustomer","persistent","review","wishlist","recently_viewed_product","recently_compared_product","product_data_storage"] }

}

}

{

"*": {

"Magento_Customer/js/customer-data": {

"sectionLoadUrl": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fen\u002Fcustomer\u002Fsection\u002Fload\u002F",

"expirableSectionLifetime": 61,

"expirableSectionNames": ["cart","persistent"],

"cookieLifeTime": "3600",

"updateSessionUrl": "https\u003A\u002F\u002Fwww.cranepartssupply.com\u002Fen\u002Fcustomer\u002Faccount\u002FupdateSession\u002F"

}

}

}

{

"*": {

"Magento_Customer/js/invalidation-processor": {

"invalidationRules": {

"website-rule": {

"Magento_Customer/js/invalidation-rules/website-rule": {

"scopeConfig": {

"websiteId": "1"

}

}

}

}

}

}

}

{

"body": {

"pageCache": {"url":"https:\/\/www.cranepartssupply.com\/en\/page_cache\/block\/render\/page_id\/268\/","handles":["default","cms_page_view","cms_page_view_id_the-process-of-a-dyno-test-on-a-liebherr-engine"],"originalRequest":{"route":"cms","controller":"page","action":"view","uri":"\/en\/the-process-of-a-dyno-test-on-a-liebherr-engine"},"versionCookieName":"private_content_version"} }

}

The three-composite sealing strip is a sealing product made of a variety of materials. The following is an introduction to it:

Structural composition:

Two dense glues: One of them is usually light-colored dense glue, which constitutes the main structural part of the sealing strip, provides basic support and sealing functions, has good wear resistance and deformation resistance, and can ensure that the sealing strip is not easily damaged during long-term use.

Sponge glue: Located in the middle or a specific position, the sponge glue is relatively soft and has a certain elasticity. Its main function is to increase the elasticity and buffering performance of the sealing strip, so that the sealing strip can better fit the installation part after installation, and play a good sealing effect. At the same time, it can also reduce the impact of actions such as closing doors or windows to a certain extent.

Internal reinforcement materials: In addition to the two dense glues and sponge glue, reinforcing materials such as reinforcing fibers and metal skeletons are usually added to the inside of the three-composite sealing strip. Reinforced fibers can improve the strength and toughness of the sealing strip, making it less likely to break; the metal skeleton can increase the rigidity and stability of the sealing strip, ensuring that it maintains its shape during use and is not easily deformed or displaced.

Performance characteristics:

Excellent sealing performance: Due to its special structural design and material combination, the three-composite sealing strip can effectively block the penetration of air, water, dust and other substances. Whether in application scenarios such as doors and windows, cars or electrical cabinets, it can play a good sealing role to prevent foreign substances from entering the internal space.

Good sound insulation performance: The presence of sponge glue and the tight structure of dense glue enable the three-composite sealing strip to absorb and block the propagation of sound, reduce the transmission of noise, and provide people with a quiet environment. For example, during the driving of the car, the three-composite sealing strip can effectively reduce the noise in the car.

Excellent weather resistance: Generally, high-quality rubber materials and special formulas are used to make it have good aging resistance, UV resistance, high and low temperature resistance and other properties. Under different climatic conditions, whether it is hot summer or cold winter, the three-composite sealing strip can maintain good performance without cracking, hardening, softening and other problems.

Strong mechanical properties: The internal reinforcement material makes it have high tensile strength, compression deformation resistance and wear resistance, can withstand large external forces, is not easy to damage, and has a long service life.

Application areas:

Automobile industry: widely used in car doors, windows, engine hoods, trunk lids and other parts of the car, which can effectively prevent rain and dust from entering the car, reduce noise inside the car, and improve the comfort and sealing of the car. At the same time, during the driving process of the car, the three-composite sealing strip can also play a role in buffering and shock absorption to protect the body parts.

Construction industry: suitable for the sealing of doors and windows, which can improve the thermal insulation, heat insulation and sound insulation performance of the building and reduce energy consumption. In building structures such as curtain walls and glass curtain walls, the three-composite sealing strip can also play a good sealing and waterproofing role.

Electrical equipment industry: used for the sealing of equipment such as electrical cabinets and distribution boxes, which can prevent dust and water vapor from entering the equipment and ensure the normal operation and safe use of electrical equipment.

Production process:

Material preparation: Select suitable raw materials such as rubber materials, sponge materials, reinforcing fibers and metal skeletons, and pre-treat them to ensure that the quality and performance of the materials meet the requirements.

Compounding process: Compound the two dense rubbers, sponge rubbers and reinforcing materials according to certain process requirements, usually using extrusion, vulcanization and other process methods to make various materials closely combined to form a whole.

Molding: According to different application requirements, the composite sealing strip is molded, such as cutting, stamping, bending, etc., to meet the size and shape requirements of the product.

Quality inspection: The three-composite sealing strip produced is strictly inspected for quality, including appearance inspection, size measurement, performance testing, etc., to ensure that the quality of the product meets the relevant standards and requirements.